FREQUENTLY ASKED QUESTIONS

-

We use common polymers which can be easily sourced and have low cost.

-

Currently, our competitors are anode material manufacturers.

-

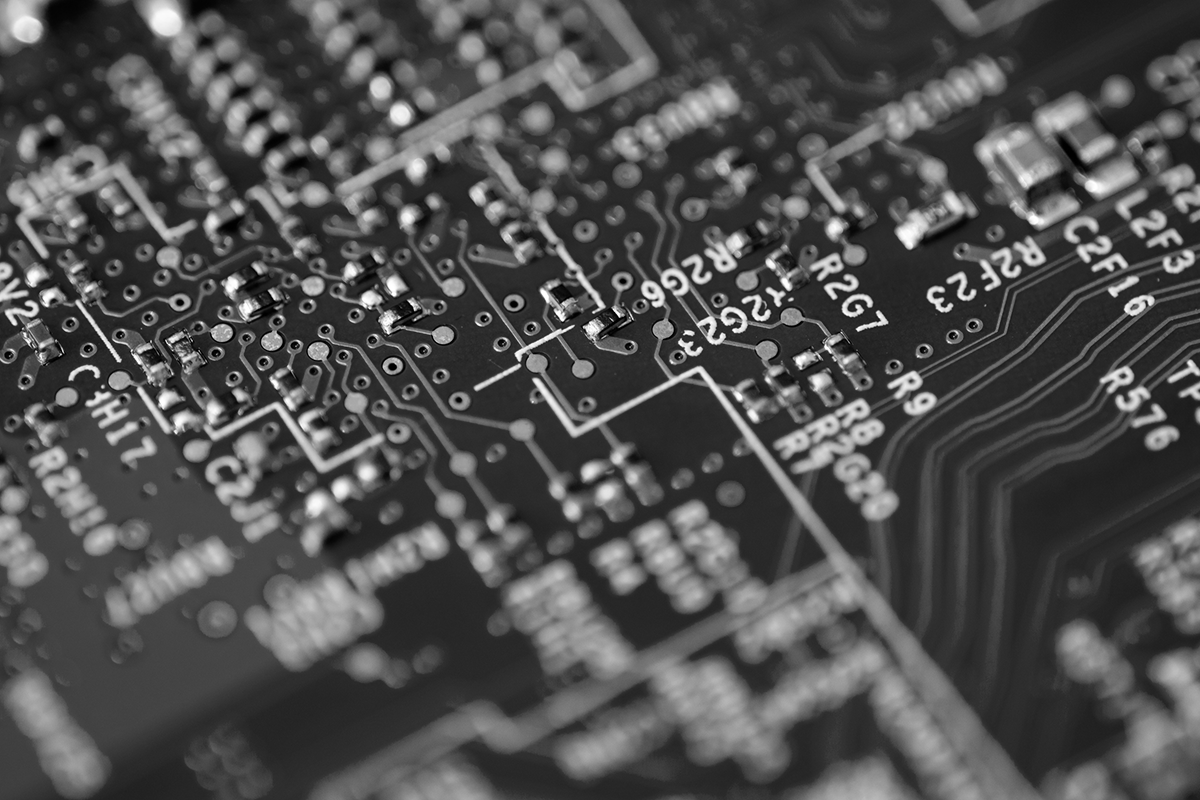

We have created an entire new kind of anode structure that is geometrically different from the current structures but can be easily fitted into current battery manufacturing processes without retooling. We have patented this new structure as its rapid charging capabilities and the amount of energy it holds are dramatically improved.

-

Our goal is to have batteries with a similar cycle life to the current graphite anode-based batteries with 1000 cycles. Our current experimental batteries are already delivering a cycle life of 700 in full coin cell, and 400 in single layer pouch cells. Those will improve as we implement the latest materials and machines.

-

They typically have huge coating lines to make the anodes and the cathodes. Our advantage is that we will supply finished anodes which they can readily integrate into their existing battery assembling lines. This will allow them to convert their current anode coating lines to cathode production, easily increasing their capabilities.

-

Different applications need different cycle life. For example, for commercial drone cycle life needs to be 150 - 300, for consumable electronics, cycle life needs to be 500. For EV, cycle life needs to be 800 - 1000. We expect to support those cycle life requirements in our finished products.

-

We currently have customers waiting for our samples for evaluation. After the samples pass the initial evaluation, we can begin the pilot manufacturing process which will generate early revenue. We expect revenue to ramp steadily from there.

-

We fully own the IP.

-

The initial prototype anodes will be created in house with existing machinery. Our manufacturing process has multiple steps and several of those can be outsourced to contract manufacturers as volume rises.